Feature 17 min read

What are solid state batteries and how will they shape the future of EV powertrains?

We take an in-depth look at solid state battery tech with Pooja Vadhva, a PhD researcher in Solid State batteries, and Pranav Nagaveykar, former Engineer at Ford in EV Battery Design.

What are solid state batteries?

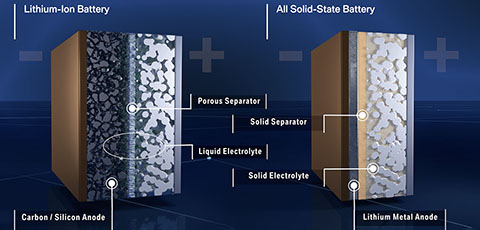

Pooja: With a conventional lithium-ion battery you have two electrodes – an anode and a cathode, and when you discharge the cell, lithium ions move across from the anode and intercalate into the cathode. The electrodes filled with a liquid electrolyte and a polymer separator is used to prevent short circuiting of the cell. The electrodes are connected to an external circuit through which the electrons flow and as you discharge the cell, current is output, which is used to power an electric vehicle. In a solid state battery, the principle is the same but you remove the separator and liquid electrolyte, and instead you have a solid electrolyte between the two electrodes. A solid electrolyte can enable a lithium metal anode which has ten times the theoretical capacity of a graphite anode, doubling the cell energy density. Lithium metal is highly reactive and can form dendrites during cycling which short circuit the cell. A solid electrolyte can mechanically prevent dendrite formation as well as increasing the safety of the cell, as you don’t have a flammable liquid electrolyte.

Pranav: Solid state batteries are basically the lithium ion batteries with no liquid electrolyte. The liquid electrolyte gets substituted by a solid electrolyte which is why these batteries are referred as solid state batteries. Many people get confused that solid state batteries are totally different type of batteries than the existing lithium ion batteries. That is not the case. It's just that the liquid electrolyte is now replaced by a solid one.

What are the main trends that are adding urgency to the need for a change in battery technology?

Pranav: As we all know everyone in battery industry is continuously working to overcome some of the major challenges for EV transition like getting more energy density, less charging time, better life cycle to name a few. With the newly developed cathodes, higher percentage of nickel, silicon embedded anodes, there has been a lot of improvement in energy density of these cells but at the same time they are also thermally less stable. Besides, the relative improvement in charging times is less. It seems like with the conventional lithium ion cells, we are approaching a saturation level with respect to all these parameters. For getting even higher energy density, better thermal stability and lesser charging times we need to shift towards a new type of technology and I believe that’s where solid state batteries come in.

Pooja: Some interesting points there. Another area where I think people don’t consider is the aviation industry, with increasing emphasis on sustainability, and there’s interest in using solid state batteries to partially or fully power electric propulsion systems on aircraft, such as during take-off or landing. NASA has also announced that it’s going to make solid state batteries for enhanced re-chargeability and safety, so this is really promising.

How do solid state batteries work?

Pranav: The basic working principal of Solid state batteries is same as the conventional lithium ion batteries. In conventional Lithium ion batteries, lithium in the cathode splits into Lithium ion and electron. The electron travel through the outer network while the Lithium ion swims through the liquid electrolyte to reach the anode. For solid state batteries, it's more or less the same. The question is – how do we move the ions from anode to cathode and vice versa? Basically we use something called diffusion – we relocate the lithium-ion positions within the solid electrolyte lattice, we create some vacancies within the current lattice structure so that the lithium ions can “hop” from one lattice position to another, moving from the anode to cathode and vice versa. That’s the only difference in the working part of the battery.

Pooja: The removal of the liquid electrolyte and separator makes the solid-state battery more compact, and with the use of lithium metal anode increases the volumetric energy density. The lithium ions hoping through the solid electrolyte lattice is a relatively fast process but you also get interfacial problems with solid state batteries, because you have a solid interface at the anode and cathode, and that can be highly resistive so that’s something to consider and is an active area of research for a lot of industries that are trying to solve this.

There’s a lot in the press that solid state batteries can be manufactured without cobalt or nickel, is this so?

Pooja: Like a lithium-ion battery, the cathode will still contain cobalt, manganese and nickel; we’re only replacing the liquid electrolyte.

Pranav: Yes the cathode will be the same. There’s a lot of confusion that solid state batteries don’t contain cobalt, manganese and nickel, but it’s not necessarily true. There is a possibility of using different cathodes but the current ones will still be in use even with solid state batteries.

Pooja: One advantage with solid electrolytes is that you can use high voltage cathodes, that have higher nickel and lower cobalt content, and this is an advantage obviously in terms of reducing cobalt as it is mostly unethically produced, and also increase energy density which is equal to the capacity multiplied by the operating voltage window. The reason that solid electrolytes can be used with high voltage cathodes is that because some solid electrolytes have an operating voltage window which is stable between 0 and 5 V, and 5 V is where a lot of liquid electrolytes soon start to decompose, (around 3-4 V). But with solid state batteries it’s not so clear what the cathode materials will be composed of. If you use a material without cobalt, nickel or manganese such as lithium iron phosphate (LFP) cathode, this is ethically better but with EV as you want a high voltage cathode for increased energy density, this would need to be be nickel-based.

Another point is how you classify the solid electrolyte materials; you have inorganic and organic electrolytes. The latter commonly uses some sort of polymer electrolytes, but because their ionic conductivity is low you don’t tend to use them for EV applications. When you look at inorganics though there are a lot of classifications – the main two are oxide and sulphur materials. Oxides are a hard ceramic and readily available, but you have to sinter them at high temperatures approximately 1000 to 1200 oC and that has a lot of cost involved. Sulphur-based chemistries are softer materials so you don’t need to process them at such a high temperature, which is an advantage, but when sulphur reacts with moisture it produces H2S gas which is toxic, so these things have to be considered when you have a production line, as well as CO2 emissions.

We discussed some of the main benefits of solid state batteries, mainly conquering range anxiety and reduced risk of fire, but what are the other advantages?

Pooja: A reduction in charging times; QuantumScape quoted that its cell can charge to 80 % capacity in 15 minutes, which is a lot less compared to the industry standard today, which is somewhere around 30-40 minutes, and one of the main reasons you can do this is because there’s no flammable liquid electrolyte in a solid state battery so you don’t need to think about an increase cell in temperature when charging at faster rates.

Pranav: As Pooja mentioned, quick charging time is going to be a great advantage with SSBs. 80% in 15 minutes means we are getting about 26% charge in 5 minutes time. Even assuming a range of 400 kms, that is like over 100kms range within in 5 minutes of fast charging time, which sound pretty impressive. Apart from that, I guess improved battery packaging is another advantage from design engineering perspective.

That’s a reduction of around 50 per cent which is pretty revolutionary.

Pooja: Exactly, and other companies have quoted similar, but these findings are from a one layer cell, this is not even a full pack yet that would be in an EV. QuantumScape have recently announced a ten-layer cell and are conducting cell testing similar to that of 1 layer cell, this needs to be accomplished and then the layers stacked into a standard pouch cell with further testing before the pouch cells are scaled to a pack for an EV.

How would factors, such as cycle-life, compare with those seen in lithium-ion batteries?

Pranav: The example with QuantumScape was it retains more than 80 per cent of its capacity after 800 charging cycles, currently commercial batteries are around 1000-1200 cycles depending on the chemistry of the battery. Some conventional lithium ion batteries even have over 2500 cycle life. I believe with Solid state batteries, we might see further development in these figures in coming years.

Pooja: On the whole the cycle life is generally lower and one reason could be these solid interfaces and the decomposition and build-up of resistive interfaces especially if you’re carrying out very aggressive cycling – this reduces cycle life and degrades the cell quicker. All these problems still need to be addressed and solved.

And in terms of being recyclable, are they any different to lithium-ion batteries?

Pooja: It’s difficult to say because no one has made a full pack yet. Recycling in principle should be possible. But will it be cost-effective to extract the materials through recycling? Ultimately, it depends on the chemistry of the solid electrolyte. The solid nature of solid electrolytes makes it easier to extract the components compared to a liquid electrolyte. And if a sulphur solid electrolyte is used, sulphur is very cheap, so it might not be effective to be recycled. If a ceramic solid electrolyte is used, which requires high temperature processing and therefore is costly to produce, and then it could justify recycling costs. I just don’t think these things have been fully considered yet as we don’t have a solid-state battery EV yet.

Pranav: Exactly. Other than the solid electrolyte part, the rest of it is the same as a conventional battery, so in terms of recycling, it should continue to progress on the same path.

Are there any disadvantages?

Pooja: Solid state batteries offer double energy density and are inherently safe. The issue is the technical challenges and scaling these into large format cells for EVs in a cost effective manner.

Pranav: In terms of progress, Solid state batteries (SSBs) are facing issues on multiple levels. From a technical standpoint, SSBs are facing issues with the electrolyte-electrode interface itself, which is the contact between the solid electrolyte and the anode and the cathode. The solid cell interface creates a lot of problems in terms of energy when the ions are flowing. There’s also a problem with the mechanical state. Solid electrolytes can possibly crack under the pressure of stacking cells when creating a battery pack. Then there is the commercialisation issue to scale these batteries to production volumes.

Pooja: I agree that production could be different but I don’t see this as a major problem. You can’t really make solid state batteries as a cylindrical cell as they are not flexible enough to wind into a cylindrical format. So current lithium-ion battery production lines would have to adapt to pouch-type cells. But there is an advantage to this because if you can eliminate the use of modules which are expensive and put cells into packs directly, yes you might have to change your cell format, but you’ll be gaining in terms of reducing weight and cost.

Longer term, the biggest problem is the pressure and dendrite issue. The solid electrolyte we talked about earlier also acts as a barrier that keeps lithium dendrites from going between the electrodes and causing a short circuit. By applying stack pressure, dendrite formation can be reduced by providing better interfacial contact. Even QuantumScape who have said their battery resolves all of the core challenges that have plagued solid state batteries, such as short lifetimes and slow charging rate, are still cycling cells at 3.4 atmospheric pressure. Can we do this in a moving vehicle? Often 1MPa is reported as viable pressure for an EV and so we should aim towards this. We need the same cell performance for solid state batteries but under a realistic pressure that we could apply just by cell stacking.

If you’re using a sulphur electrolyte, there’s still an issue in a crash with sulphur being exposed to air and causing toxic gases to be released. Oxide electrolytes do not produce such toxic gases, but require high temperatures for sintering which is expensive. So, there is a trade off between reduced electrolyte sintering temperature for sulphur electrolytes and the cost associated with building moisture sensitive chambers.

The other issue is building enough gigafactories to reduce the overall manufacturing cost of solid state batteries as they will be more expensive than lithium ion even if the initial chemistry costs are less.

Bloomberg New Energy Finance quotes the price of solid-state cells won’t drop below current liquid-electrolyte lithium ion cells until 2034. Do you think that’s accurate?

Pranav: That sounds about right with the current state. There is not even a proper full scale model available yet. The commercialisation part may depend on how the productions of these cells are adapted.

Pooja: To say if it's specifically 2030s or 2034 is very difficult because these companies are looking at different solid electrolyte materials and all the costs associated and the production line will be different, so it’s too early to say but I don’t see them being any cheaper than lithium-ion batteries before this timeframe.

Can solid state batteries still operate at a wide range of temperatures?

Pooja: Yes, they actually have an advantage because they’re not flammable so you can take them to higher temperatures and even at lower temperatures where dendrites seem to form. So while the pack is slightly more expensive, it can be used in more applications such as aerospace or high performance vehicles which may require a high temperature range during operation. As EVs become popular though companies can achieve economies of scale by increasing production and lowering costs.

Pranav: Yes that is one of the major highlights of solid state batteries. Wide temperature range.

Given they’re more stable, I guess that means they don’t require expensive cooling systems?

Pranav: Yes. they don’t need expensive cooling systems. There is a possibility they may not require any cooling system. Also it means EVs manufacturers can use that space to fit more batteries or package the existing battery size more efficiently.

Pooja: Yes exactly, and that can help lower the production costs, too.

In what applications will we see first gen solid state cells and why?

Pranav: Passenger electric vehicles, there’s a lot of research going on in terms of aviation as we mentioned, so that could come up an as one of the application but from what I’ve read, we will first see them in EVs.

Pooja: Yes, I agree, but I would probably say more luxury EVs, because of the cost. Any application where safety and energy density is paramount and cost is not an issue that’s where we’ll see it first, so aviation as Pranav said. I would say for grid scale or marine applications where you want batteries to be very cheap and it doesn’t matter about the energy density or the size then industries won’t look to solid state.

Some battery technology developers are quoting 2026 as a target to start delivering their solid state batteries, such as Oxis Energy, while car maker’s like BMW are touting 2025 with a demonstrator vehicle. Is there a feasible timeframe given solid state cells are still commercially unproven and no one as yet has managed to transition from hand-made samples to scaling up both cell size and production volume to the point where it would actually be practical to power a vehicle?

Pranav: All car manufacturers have to set up a timeline for any project, and 2025 is an aggressive target, although entirely possible for a demo, but I don’t see it being production ready by then.

Pooja: I would say from an academic side, we first need to solve the dendrite issue. Let’s say we take QuantumScape’s word that they have solved the dendrite issue, and then at the moment they have a ten layer cell which will form part of a single pouch cell. Their initial cycling tests have been done on a single layer cell so they need to reproduce these results on their ten layer cell. Once the ten layer cell performs well, they need to integrate these pouch cells into a pack, which will be one to two years and then they’ll need to try it in a prototype vehicle, and in tandem build a production line. Firstly, we’d have to see, if once they put it into a full pack, they are getting the performance they need to see if it’s worth scaling for gigafactories.

Solid Power is another company that has made a 2Ah pouch cell and they’re currently manufacturing 20Ah. Even though the timescales are quite far I think in the next year or two we will be able to at least know if this is going to be commercial and integrated into EVs with the aforementioned issues solved. That’s when it will be time to get excited, but it’s not far off: moving from labs into manufacturing and, if it proves its worth, with enough money and investors, to rapidly make production line facilities.

Volkswagen sees the solid-state battery as the end game in battery tech, cutting charging time by 50 per cent while increasing range by 30 per cent at the same time. Would you agree? Will solid-state batteries ever replace lithium-ion?

Pooja: I think both are needed, and in cases of superior applications such as performance/luxury EVs where performance and safety is paramount we’ll have solid state, but I don’t see lithium-ion going away anytime soon, it’s quite cheap and for things like energy storage systems, it’s perfect, because of their rapid response, modularization, and flexible installation.

Pranav: I also agree with Pooja, at least for the next few decades and until the costs of solid state batteries come down we’ll see them both being used. And in terms of VW’s statement I think we could see range increase by up to 50 per cent.

What companies should we be keeping an eye on in terms of those looking to shake up the electric vehicle industry by using solid-state batteries?

Pooja: That’s quite a few, there’s Samsung, who teamed up with Toyota. Honda and Nissan, then there is Solid Power who BMW and Ford are heavily invested with – who use a sulphur electrolyte which is different to QuantumScape who are using a ceramic electrolyte. Solid Power is also looking to have a silicon anode, which is interesting as the industry mostly uses lithium anodes. There’s Solid Energy Systems which General Motors is partnering with and they use a hybrid electrolyte system –a solid polymer electrolyte to protect the lithium anode but have a liquid electrolyte.

Pooja Vadhva

Pooja Vadhva  Pranav Nagaveykar

Pranav Nagaveykar  Li-Ion battery vs all solid-state battery

Li-Ion battery vs all solid-state battery  Inside QuantumScape's battery lab

Inside QuantumScape's battery lab  QuantumScape has successfully stacked their single-layer cells, and now says it will develop multilayer solid state battery cells when it moves to pilot production

QuantumScape has successfully stacked their single-layer cells, and now says it will develop multilayer solid state battery cells when it moves to pilot production  BASF to build new battery recycling prototype plant in Schwarzheide, Germany

BASF to build new battery recycling prototype plant in Schwarzheide, Germany  Pure electric Volvo C40 and XC40 recharging at a charging station

Pure electric Volvo C40 and XC40 recharging at a charging station  The BMW Group and Ford are aiming to utilise Solid Power’s low-cost, high-energy all solid-state battery technology in forthcoming electric vehicles

The BMW Group and Ford are aiming to utilise Solid Power’s low-cost, high-energy all solid-state battery technology in forthcoming electric vehicles

Comments (0)

Be the first to write a comment

Login/ Signup