Feature 14 min read

StoreDot and BP present 5 minute charge of e-scooter

Fossil fuel giant, BP, team up with battery materials innovation leader StoreDot, to make a contribution to the world’s ambition of transitioning to EV with the ability to recharge a battery in just five minutes.

BP is one of the world's seven oil and gas supermajors – and while it has almost 20 million barrels of oil in its reserves and 63,000 square kilometres of new exploration access, the world is still demanding more energy. But things are a little bit different to when explorer George Reynolds first started drilling for oil in the early 1900s, people are demanding energy that is cleaner and better, and BP is looking to the future as it aims to make bold changes in how it mobilises the motorist.

Why does BP have an interest in this area?

John Salkeld (pictured below), Technology Director of BP’s Advanced Mobility Unit (AMU), says that there is a seismic shift in the way people and goods travel around the world and that it is coming from three big drivers: technology (electric vehicles, batteries and big data processing); consumers (who are rapidly changing their views and embracing shared mobility, on-demand services and touch-screen convenience); and cities (which are trying to keep people moving while dealing with congestion and pollution).

All of these factors are driving a different future, and the crux of it is electric vehicles play an incredibly important role in all of this. As car manufacturers offer the public more choice and the charging infrastructure improves, people will start to make the shift to zero emissions motoring, and that ultimately means less demand for oil. There are currently only five million EVs in the world but going by current trends, BP themselves believe that by 2040 that figure could be as high as 350 million. Being able to charge a car as fast as you can fill up with petrol and diesel however, will be critical to mass adoption says Salkeld.

When we think of ultra-fast charging today its being able to achieve 100 miles of range in 10 minutes, which equates to a charging rate of 150kW – and to that end BP launched their first ultra-fast charging station in Germany (which incidentally can be upgraded to 320kW). Last year they acquired Chargemaster, the UK’s biggest electric car charger network, and by the end of the year, 100 Ultracharge 150kW chargers are due to be installed at 50 BP forecourts, and 400 of the units will be at petrol stations by the end of 2021. And that’s good news, given BP’s findings from a study that it did with National Grid in the UK, in which just 50 ultra-fast charging stations located at strategic places in the UK would mean that 95 per cent of the population would be within a short drive of a charging station.

But by BP’s own admission it will take a lot of hard work to make ultra-fast charging a reality, firstly in terms of helping consumers to understand what it’s all about but also the impact on infrastructure. If there’s no way for consumers to charge at home they’ll need to find a charging point elsewhere that’s convenient and for those travelling long distances for work or to visit family and friends destination charging will be key, likewise for commercial drivers, for whom every hour the car is spent charging, is losing them money.

“We will need to strengthen the grid to allow any form of mass charging at home or on a forecourt, but we also need the cars themselves. The fastest charging production car at the moment is a Model 3 which can be charged at 200kW, next year we’ll see the Porsche Taycan with 350kW capability [adding more than 60 miles of range in four minutes] but these are still premium vehicles and we won’t rest until that capability is available for the mass market of consumer vehicles,” reveals Salkeld.

What else is BP doing to uphold its part in mapping out the road to ultra-fast charging?

Last month it held a conference with CharIN (an association whose aim is to develop and establish Combined Charging System DC fast and ultra-fast charging), where they brought together 200 people from around the world involving all of the industry’s key players including their competitors, government decision makers and city authorities.

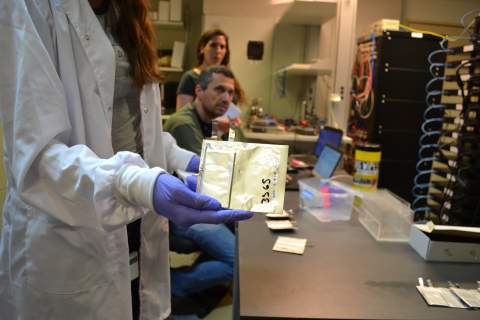

One of the linchpins to achieving ultra-fast charging is battery technology, and when BP took that view, they reached out to the industry and Store Dot appeared as leaders in this field. So, 18 months ago they invested 20 million dollars to help with the production of these batteries, but it goes beyond the financial investment. They’re very keen to bring the technology forward to market and that’s why they’ve worked very hard with the StoreDot team to put together this demonstration at the EcoMotion event in Tel Aviv, Israel, that saw the tech company take an off-the-shelf Muvi electric scooter from Spanish firm Torrot and replace the cells with its FlashBattery technology in a 7kg battery pack.

Who are StoreDot?

StoreDot was founded in 2012 out of Tel Aviv University with the idea that they could take new materials such as metalloids together with organic compounds in order to change the world of energy storage and optimise those materials for ultra-fast charging. Thus far the cell manufacturer has raised a total of £130 million from some of the industry’s biggest players including Samsung, BP, Daimler and TDK Corporation, so they have home electronics side of the market covered, and then in terms of automotive, the infrastructure for the vehicle, the vehicle itself and the manufacturing capabilities. The 115 strong team (including 35 PHDs) are based at its state-of-art laboratory in Herzliya, includes 30 PHDs and more than 50 engineers in the multidisciplinary field of organic chemistry, material science, physics and electrochemistry.

StoreDot started with its 2.5 amp PD (Power Delivery) standard FlashBattery for smartphones – an instant-charging battery that can fully charge in just five minutes. It’s actually capable of delivering up to 10C, or 5 amp (and also higher voltage), achieving a remarkably rapid charging rate that is up to 100 times faster than any other mobile device battery, fully juicing a smartphone in 60 seconds, but it would require a much larger charger. This 100 watt battery (similar to a laptop) is only five cubic inches so it was a much easier introduction to the market and it will be available next year. The next step will be fitting its battery to the phone rather than in the power bank.

I ask founder and CEO of StoreDot Dr. Doron Myersdorf whether the fast charging has any detrimental effect to the FlashBattery. “We had to optimise the number of cycles it would do, so after 500 cycles of charging, the battery will deplete to 80 per cent and will continue to deteriorate. This is always a compromise between energy density and how many cycles you want to achieve and we have the same challenge with the electric scooter for which we’re targeting 1000 cycles, and in an EV about 1500.”

Talking of which, what followed was a new type of electric-car battery consisting of proprietary organic compounds – based on the innovative materials used in its FlashBattery for mobile devices. StoreDot believe range anxiety is the number one barrier today for the adoption of EVs, and while everyone is saying it’s impossible to charge in the same amount of time as it takes to stop for petrol, they have shown that it is possible and they plan to roll it out in a few years.

So how have they done it?

Unlike its competitors StoreDot has completely re-engineered the battery. So it’s still lithium-ion, the mechanism of transferring the current from anode to cathode, but the battery components do not contain graphite which is the number one problem with fast charging and why the Galaxy Note 7 kept exploding. It’s because of the resistance, the heat, and the inability of the lithium to diffuse quickly into the active material.

The active material used in StoreDot’s FlashBattery is a batch of metalloids (a semi-conductor), which uses silicon, germanium and tin. These nano particles are coated with organic molecules. While organic materials are good for the environment the battery still uses lithium and cobalt, but StoreDot is trying to reduce the amount of cobalt, so they’re moving from something called NMC 622 to NMC 811. The numbers refer to the ratio of nickel, manganese and cobalt in the cathode material. NMC 811 is the latest commercially available iteration, which as the ratios suggest, has an increased nickel content and less manganese and cobalt than its predecessor, NMC 622.

“Our second generation of battery will be even better for the environment but this is still five years away. It’s the design of the electrochemical reactions that need to be re-thought with an environmental focus and we have the best team in the world to take on such a task. First though we need to launch the ultra-fast charging technology in order to gain traction in the market and show whatever we do in the lab is commercially viable and show some revenue, and that will give us the credibility to evolve the industry and achieve our ambitions to produce a greener battery. Our gen three batteries won’t have any cobalt in at all,” says Myersdorf.

I ask Myersdorf if it’s a problem sourcing the materials: “We are developing equipment to treat the materials so they will be optimised for fast charging. So there are two things to consider: one is to reduce the size of each particle to be Nano metric, this allows very fast diffusion of the ions as you charge, and the other thing is the organic coating – these are small molecules of organic material that we synthesise on-site, the same way you would do to develop a drug or pharmaceuticals, and they protect the silicone. And then we have the scale up where we put everything together to build the battery. So, obtaining the materials isn’t a problem, it’s a problem to bring them to the right properties so it will be electrochemically optimised for fast charging. And that’s also part of the challenge when we’re asked when this will be available for mass production. Part of this is the build-up of the supply chain and it will be a few years, because you can buy the materials but you still need to process them in large volume.

“We are trying to achieve a break-through in the chemistry of the cell because this is the limiting factor today in trying to achieve fast charging. In a lithium ion battery the electrolyte is the lithium ions that move from anode to cathode or the other way around. When this happens it creates movement of electrons and this is the electricity you get from the battery. Generally what you do is you prepare what we call a ‘slurry’, which is the wet part of the process where you mix all of the materials together, which you then put on foil to transform all of the current,” says Myersdorf (pictured below).

He goes on to add: “It’s then put into an oven to dry and the electrodes, which are coded both sides, are cut to roughly the size of credit cards. To make the battery we stack them – anode over cathode, anode over cathode – until we achieve the desired amount of energy for the cell. The cell is sealed and after that it goes through a formation process which gives the cell its electro capable properties.”

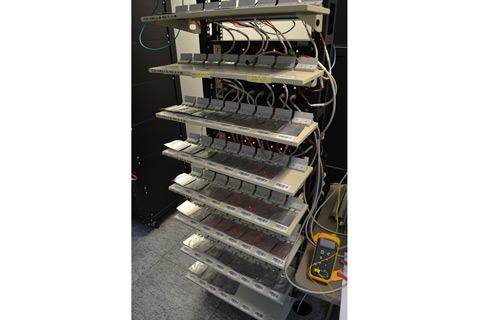

Seven years in the making, the battery has 14 modules in serial, each one with 12 cells, and each one 1 amp hour. Total capacity is 13 amp hours, roughly 0.75kwH.

StoreDot then work with partners such as Armicell to integrate the cells into a final product. Each cell voltage is tested and aligned in-house, with low internal resistance to enable the fast charge. StoreDot has also added anti-degradation agents into the battery chemistry to address the issue around the problems facing fast charging batteries (rapid wear of batteries).

Until now they had never tried to make the cell into a product and the idea of demonstrating their ability to fast charge their scooter battery in five minutes came from BP, so it was with bated breath that the world’s press watched this compelling event.

The world-first demo

The battery started with 15 per cent charge (with 20 kilometre range), and it was placed in a charger that had fans to enable cooling with charging. It was then hooked up to a live screen showing voltage, temperature, amp hours, percentage of battery and time lapse.

The charge started at 43 volts (the discharge and pulse charge varies from 40 to 50, which is their cut-off) and an outside temperature of 33 degrees (it can go up to 45 degrees before shutting down) and 130 amps, which is the ideal charging current. When they tested it previously the outside temperature never reached higher than 32 degrees, but despite climbing to 37 degrees, 5 minutes 10 seconds later it reached 100 per cent charge, compared to the normal charging time of about four hours, giving the scooter enough juice to go 70 kilometres. That's quite impressive and is definitely advantageous when undertaking long journeys.

Although this equates to a similar miles per hour charge rate to a current Tesla Model S battery, the important thing is that the battery technology is scalable, making it possible to charge much larger packs, by which time we could see 350kW charge points becoming widespread along motorway networks across Europe, making StoreDot’s technology the missing piece of the puzzle is the chemistry that allows for a full five minute charge, rather than just a top-up.

What does the future hold?

StoreDot together with BP plan to put its scooter batteries on the market in 2021, when it also says it will be able to charge a Daimler and Mercedes-AMG model in five minutes. The automobile battery will need ten times as many power cells as the scooter battery, and an even more efficient way of cooling while in use, says Myersdorf. To that end it’s also worth noting StoreDot is in talks to build its proposed Gigafactory in either the US or Europe, which would commercialise and produce its FlashBattery technology for the mass market.

We’ll leave the last words to Myersdorf: “Instead of doing what everyone else is doing which is trying to extend the range between charges we are taking a different approach which is an alternative way to mitigate the range anxiety which is ultra-fast charging, so the experience is similar to re-fuelling a conventional car without the fumes. There are many things that need to fall into this place in order for this to happen. One is the infrastructure as John said earlier, with the grid capabilities and looking at how that can support mass adoption of EVs and the charging station that needs to have at least 350kW power. Then there should be a tiered approach to charging with prices staggered according to different rates of charge, which will also help to optimise the life of the battery.

“The real game changer is if the battery itself can take the entire power – zero to 100 per cent – in five minutes and that’s what we’re aiming for. BP tell us, that according to data released by Fastned, the actual very high charging only occurs for a few minutes and then drops straight down again in order to protect the battery. With our technology there is much less resistance with the materials so you can stay in what is called a constant current mode enabling a full charge in five minutes. Some of the bigger players are showing that they can achieve a 30 minute full charge in a few years, so what StoreDot has achieved is a leap in terms of the capabilities of the industry.”

Comments (1)

Login/ Signup

LEAF me alone!

27/06/2019 04:25

Very interesting article on batteries. As we now have 300 mile range EVs at more reasonable prices, still expensive compared to their ICE counterparts, from the Koreans, charging speed is the only real argument left for the fossil fuel loving naysayers. Battery technology is clearly still in early days and obviously will improve, this article suggests a lot quicker than was thought possible. Can't come soon enough if we are to dramatically reduce carbon emissions and avoid climate catastrophe.